Back to Product Category

FIXED STEEL LADDERS

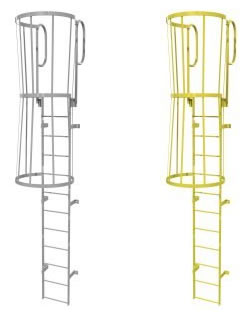

SERIES WLFS & WLFC |

WALK-THRU

AND STANDARD |

|

|

|

|

|

|

|

|

|

|

•

Side rail 2 - 1/2” x 3/8” flat bar

• Solid round 3/4” rungs

• 12” spacing between rungs

• 18” ladder width

• 42” guardrails on walk-thru models

• Powder-Coat Gray or Safety Yellow Finish (WLFC)

(WLFS comes only in Safety Yellow Finish)

• Complies with applicable OSHA & ANSI standards |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fixed ladders

are shipped in a box. Standard ladder

sections, in rung lengths from 4-7 steps, are combined

to form a finished kit. A boxed walk-thru section can

be added as well. Boxed ladders provide huge freight

savings! |

|

|

|

|

|

|

|

WLFS

Yellow Only |

|

|

|

|

WLFC

Yellow or Gray |

|

NOTE:

• Ladder drawings are available by clicking Model #.

• See Fixed Ladder Requirements at bottom of page.

• Ladder mounting table is shown below price tables.

• Optional ladder door guard is listed below price tables. |

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to purchase. |

|

|

PRICING

FOR FIXED STEEL LADDERS WITHOUT CAGE IN SAFETY YELLOW FINISH ONLY

(Click

the Model No. for Drawing Dimensions) |

Model No. |

Shipping Dimension |

#

of

Rungs |

Length

top to

Bottom Rung |

Weight

(lbs) |

Price |

WALK-THRU

LADDERS |

|

48"

x 40" x 14" |

4 |

3' |

122 |

|

|

60"

x 40" x 14" |

5 |

4' |

131 |

|

|

72"

x 40" x 14" |

6 |

5' |

142 |

|

|

85"

x 40" x 14" |

7 |

6' |

151 |

|

|

48"

x 40" x 17" |

8 |

7' |

174 |

|

|

60"

x 40" x 17" |

9 |

8' |

183 |

|

|

60"

x 40" x 17" |

10 |

9' |

192 |

|

|

72"

x 40" x 17" |

11 |

10' |

203 |

|

|

72"

x 40" x 17" |

12 |

11' |

214 |

|

|

85"

x 40" x 17" |

13 |

12' |

223 |

|

|

85"

x 40" x 17" |

14 |

13' |

232 |

|

|

60"

x 40" x 21" |

15 |

14' |

253 |

|

|

72"

x 40" x 21" |

16 |

15' |

264 |

|

|

85"

x 40" x 21" |

17 |

16' |

273 |

|

|

72"

x 40" x 21" |

18 |

17' |

286 |

|

|

85"

x 40" x 21" |

19 |

18' |

295 |

|

|

85"

x 40" x 21" |

20 |

19' |

304 |

|

STANDARD

LADDERS |

Model

No. |

Shipping

Dimension |

#

of

Rungs |

Length

top to

Bottom Rung |

Weight

(lbs) |

Price |

|

48"

x 40" x 8" |

4 |

3' |

92 |

|

|

60"

x 40" x 8" |

5 |

4' |

101 |

|

|

72"

x 40" x 8" |

6 |

5' |

112 |

|

|

85"

x 40" x 8" |

7 |

6' |

121 |

|

|

48"

x 40" x 11" |

8 |

7' |

144 |

|

|

60"

x 40" x 11" |

9 |

8' |

153 |

|

|

60"

x 40" x 11" |

10 |

9' |

162 |

|

|

72"

x 40" x 11" |

11 |

10' |

173 |

|

|

72"

x 40" x 11" |

12 |

11' |

184 |

|

|

85"

x 40" x 11" |

13 |

12' |

193 |

|

|

85"

x 40" x 11" |

14 |

13' |

202 |

|

|

60"

x 40" x 15" |

15 |

14' |

223 |

|

|

72"

x 40" x 15" |

16 |

15' |

234 |

|

|

85"

x 40" x 15" |

17 |

16' |

243 |

|

|

72"

x 40" x 15" |

18 |

17' |

256 |

|

|

85"

x 40" x 15" |

19 |

18' |

265 |

|

|

85"

x 40" x 15" |

20 |

19' |

274 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

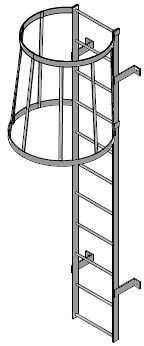

Standard

Ladders W/Cage

WLFC11 Series |

|

Walk-Thru

Ladders W/Cage

WLFC12 Series |

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to purchase. |

|

|

PRICING

FOR FIXED STEEL WALK-THRU LADDERS WITH CAGE

(Click

the Model No. for Drawing Dimensions) |

Powder-Coat

Gray Finish |

Safety

Yellow |

Weight

(lbs) |

#

of

Rungs |

Length

top

to Bottom

Rung |

Model

No. |

Price |

Model

No. |

Price |

|

|

|

|

241 |

11 |

10' |

|

|

|

|

262 |

12 |

11' |

|

|

|

|

282 |

13 |

12' |

|

|

|

|

299 |

14 |

13' |

|

|

|

|

313 |

15 |

14' |

|

|

|

|

338 |

16 |

15' |

|

|

|

|

357 |

17 |

16' |

|

|

|

|

377 |

18 |

17' |

|

|

|

|

385 |

19 |

18' |

|

|

|

|

407 |

20 |

19' |

|

|

|

|

427 |

21 |

20' |

|

|

|

|

445 |

22 |

21' |

|

|

|

|

460 |

23 |

22' |

|

|

|

|

481 |

24 |

23' |

|

|

|

|

501 |

25 |

24' |

|

|

|

|

521 |

26 |

25' |

|

|

|

|

547 |

27 |

26' |

|

|

|

|

567 |

28 |

27' |

|

|

|

|

587 |

29 |

28' |

|

|

|

|

607 |

30 |

29' |

|

|

PRICING

FOR FIXED STEEL STANDARD LADDERS WITH CAGE

(Click

the Model No. for Drawing Dimensions) |

Powder-Coat

Gray Finish |

Safety

Yellow |

Weight

(lbs) |

#

of

Rungs |

Length

top

to Bottom

Rung |

Model

No. |

Price |

Model

No. |

Price |

|

|

|

|

202 |

11 |

10' |

|

|

|

|

223 |

12 |

11' |

|

|

|

|

243 |

13 |

12' |

|

|

|

|

260 |

14 |

13' |

|

|

|

|

274 |

15 |

14' |

|

|

|

|

299 |

16 |

15' |

|

|

|

|

318 |

17 |

16' |

|

|

|

|

338 |

18 |

17' |

|

|

|

|

346 |

19 |

18' |

|

|

|

|

368 |

20 |

19' |

|

|

|

|

399 |

21 |

20' |

|

|

|

|

406 |

22 |

21' |

|

|

|

|

421 |

23 |

22' |

|

|

|

|

442 |

24 |

23' |

|

|

|

|

462 |

25 |

24' |

|

|

|

|

482 |

26 |

25' |

|

|

|

|

508 |

27 |

26' |

|

|

|

|

528 |

28 |

27' |

|

|

|

|

548 |

29 |

28' |

|

|

|

|

568 |

30 |

29' |

|

|

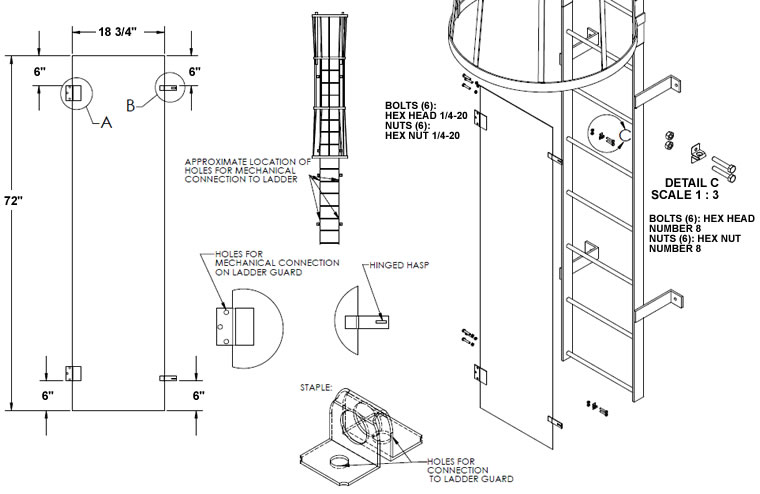

FIXED

LADDER DOOR GUARD INSTALLATION GUIDE |

| OPFS03

DOOR GUARD .............................................................................................................................. $500.40 |

|

| DIRECTIONS |

1.CLAMP

GUARD TO LADDER

2.USING EXISTING HINGES HOLES, MARK LADDER FOR DRILLING

3.REMOVE GUARD AND DRILL HOLES

4.MOUNT GUARD WITH SIX 1/4-20 HEX HEAD BOLTS

5.CLOSE GUARD OVER LADDER

6.USE THE CLOSED HASPS TO ASSIST IN LOCATING AND MARKING THE HOLES

TO MOUNT THE STAPLES

7.MOUNT STAPLES USING SIXNUMBER 8 HEX HEAD BOLTS

8. THE LADDER IS NOW READY FOR USE |

|

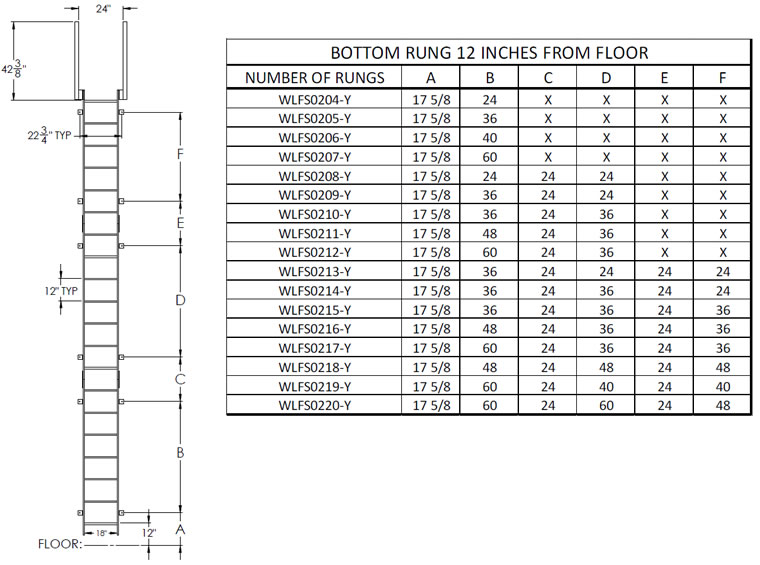

WLFS

MOUNTING TABLE |

|

|

STEEL

FIXED LADDERS REQUIREMENTS |

|

|

Fixed

ladders are the subject of strict guidelines from OSHA and ANSI, the two

organizations most responsible

for setting and maintaining safety standards in the United States. Some

of the regulations are difficult to navigate,

and some have recently changed. |

|

|

What

are fixed ladders?

Fixed ladders, as defined by OSHA, 29 CFR 1910.21, are ladders “with

rails or individual rungs that (are) permanently

attached to a structure, building or equipment.” These ladders provide

access to places ranging from the rooftop of an

office or apartment building to the highest levels of a warehouse, or down

to the waterline from a boat dock or to an

underground site. |

|

|

| OSHA

and ANSI standards for fixed ladders |

|

|

OSHA,

the federal government’s Occupational Safety and Health Administration,

and ANSI, the nonprofit

American National Standards Institute, have set down detailed regulations

on the construction and use of fixed ladders. |

|

|

| They

include detailed instructions on, to name a few things: |

|

|

|

• The spacing

of rungs.

• The width between side members, which are the vertical railings on

each side of the ladder.

• The length of stand-off brackets. These are the fixtures that attach

the ladder to a wall and establish the distance

between the ladder and the building.

• The degree of pitch, the angle between the vertical wall and the

leaning ladder. The ideal pitch of a fixed ladder

is 75 degrees to 90 degrees from the horizontal.

• The height that side rails should extend beyond the landing surface,

such as the roof.

• The load amount allowed per ladder.

• The placement of grab bars. |

|

|

OSHA

and ANSI standards for vertical fixed access ladders cover many other issues,

including clearance, rest

platforms and clear width. And the regulators sometimes update the rules.

A major change in safety standards

for fixed ladders occurred several years ago. |

|

| Fixed

ladder requirements have changed |

|

Previously,

fixed ladders longer than 24 feet were required to have either cages or

wells to help ensure the safety

of the people climbing them. |

|

The

value of cages and wells was questioned, however, and on Jan. 17, 2018,

the regulations changed. Cages

and wells were being phased out, except in certain grandfathered-in cases,

and personal fall arrest systems (PFAS)

and ladder safety systems (LSS) were being phased in for ladders of 24 feet

or more. |

|

By

Nov. 18, 2036, grandfathered-in or not, “All fixed ladders must be

equipped with a ladder safety or personal

fall arrest system.” |

|

| What

safety measures apply to fixed ladders? |

|

Let’s

take a look at the differences between different types of fall protection:

cages, wells, personal fall arrest

systems (PFAS) and ladder safety systems (LSS). |

|

Cages

and wells

OSHA calls a cage a type of basket guard “enclosing or nearly enclosing

a ladder’s climbing space and fastened

to one or both of the ladder’s side rails or to another structure.” |

|

Basically, a cage is affixed

to a ladder’s side rails and does not always provide 360-degree coverage.

A well is

“a permanent complete enclosure around a fixed ladder,” or a

permanent cage that provides 360-degree coverage. |

|

Both cages and wells prevent

people from making big, unintentional lateral movements, or movements

back and

away from a ladder. |

|

However,

the biggest danger in ladder accidents comes from the fall. Once someone

starts falling, he can get

seriously injured by hitting sections of the cage or well, and also become

entangled in them. |

|

| Personal

fall arrest system |

|

PFAS

and LSS are designed to stop someone’s fall quickly and safely. A PFAS

(which most people have seen in

any movie showing a window washer on the side of a high-rise building) is

composed of a harness tethered to an

anchor secure enough to withstand the weight of someone falling. Instead

of crashing to the ground or hitting sections

of a cage or well, the person would be suspended briefly until he can regain

his footing. |

|

| Ladder

safety system |

|

An

LSS is similar to a PFAS in that a harness is worn. However, the harness

is hooked to a pulley system embedded

into or attached to the side of the ladder. This system kicks into action

only when a fall occurs, similar to the way a

car’s seatbelt works only during a sudden stop. |

|

Again,

by Nov. 18, 2036, all fixed ladders longer than 24 feet will be required

to be equipped with either a PFSA

or a LSS. |

|

Steel

is much heavier than aluminum, which means that steel ladders are much more

durable and resilient. However,

steel rusts over time unless treated with an anti-rust agent. Our paint

system for its fixed steel ladders ensures a top-

notch finish. And its all-welded production and “state-of the-art robotic

weld cell” minimize rust to a non-issue. |

|

A vertical fixed access ladder

also should allow easy access to the climber’s destination, be it

a rooftop or a dock.

Thus, proper walk-thru handrails, or the part of the ladder through which

one passes to step on a rooftop or dock,

are vital. The walk-thru rails of our fixed ladders are designed for easy

access and egress. |

|

The

texture of the rungs is another major issue. Rungs should grip shoes instead

of encouraging Marx-Brother-type

pratfalls. Perforated steel treads are kind of like the old-school cheese

graters with upward-facing holes and down-

ward-facing slots for gripping and for drainage. |

|

|

Fixed Steel Ladders, Fixed

Steel Walk-Thru Ladders, Fixed, Walk-Thru Handrails, Ships In Box, Stainless

Steel Construction, Fixed

Ladders with Safety Cages, Standoff Landing Platforms with Offset Caged

Ladders, Security Cage Entry Gate, and Security Ladder

Guard from your source for material handling equipment. |

Back to Product Category

|