Back to Product Category

Mini-Mark

II Air-Lift System

|

|

|

|

|

|

|

|

|

|

|

|

|

Like

our standard Mark II, the Mini-Mark II Air-Lift

System is a durable and reliable pressure/vacuum system

that requires power only at one end of the system. The

Mini-Mark II System moves carriers in one direction

using pressure and with vacuum power on return to

provide a highly dependable "push-pull" operation. The

smaller Mark II System is ideal for a wide range of

industrial, retail and commercial applications, requiring

only minimal counter space. The installation of

intermediate stations provides the capability to expand

your system for even greater flexibility. |

|

|

|

|

|

|

|

|

|

|

|

|

|

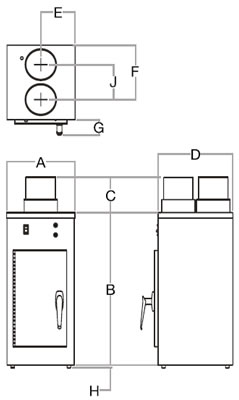

Powered

Station Dimensions |

|

|

|

System Size |

3" |

4" |

A |

9 1/4" |

9 1/4" |

B |

20 5/8" |

20 5/8" |

C |

4 3/4" |

4 3/4" |

D |

10 1/8" |

10 1/8" |

E |

4 5/8" |

4 5/8" |

F |

6 7/8" |

7 1/4" |

G |

7 7/8" |

1 7/8" |

H |

3/4" |

3/4" |

J |

4 1/4" |

4 3/4" |

|

|

|

|

|

|

|

|

|

|

Electrical

Requirements |

|

|

|

|

|

|

|

|

|

Power,

all models: 115V, single-phase, 60 Hz |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

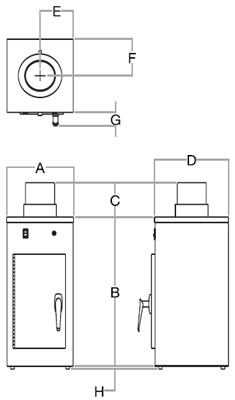

Non-Powered

Station Dimensions |

|

|

|

System Size |

3" |

4" |

A |

9 1/4" |

9 1/4" |

B |

20 5/8" |

20 5/8" |

C |

4 3/4" |

4 3/4" |

D |

10 1/8" |

10 1/8" |

E |

4 5/8" |

4 5/8" |

F |

4 3/4" |

4 3/4" |

G |

1 7/8" |

1 7/8" |

H |

3/4" |

3/4" |

|

|

|

|

|

|

|

|

|

|

Down

Send Stations Available |

|

|

|

|

|

|

|

|

|

Requires

control cable between stations. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pneumatic

Dispatch |

|

|

|

|

|

|

|

|

Perfect

For Warehouses, Transportation, Industry... |

|

|

|

|

|

|

|

|

If

you're wasting money moving things in your business, then you should look

into the Economical, Fast, Reliable

Dispatch Systems. Air-Lift systems completely eliminate the need for messengers

in most operations... Eliminate

their wages, benefit packages, coffee breaks, and time taken from more productive

work... and deliver the goods

ten times faster!

Dispatch systems are compact and high-capacity, providing two-way carrier

travel in a single tube. Installation is

so easy, your own employees can set it up in less than a day! No complicated

power wiring. Just plug the system

into an existing wall outlet and start using. No other pneumatic tube system

can deliver paperwork, parts or

samples from one location to another with the ease, speed, low cost and

safety of a Dispatch System. Low-cost,

automatic, instantaneous dispatch system designed to convey materials between

two similar Send/Receive Stations

through a single connection tube.

Air-Lift Pneumatic Systems can deliver anything that fits in an Air-Lift

Carrier to any remote location - even on

different floors or in other buildings - in a few seconds. Small parts,

orders, invoices, credit cards, shipping papers,

memos, currency, mail, laboratory or test samples, medical supplies, or

any other load weighing up to 5 lbs, are

whisked at speeds up to 25 feet per second on a jet-stream of low-pressure

air to a destination up to 2,000 feet

away. Our flexible systems deliver upward, downward, or in any direction,

not just horizontally. And they are

energy efficient; the blower operates only when a Carrier is in transit,

not 24 hours a day as many other systems do.

Unlike old-fashioned, bulky, twin-tube vacuum systems consisting of heavy

steel tubing and low-capacity carriers

plus expensive three-phase turbo-compressors requiring additional complex

controls, the Air-Lift Pneumatic

Systems are compact and high-capacity, providing two-way carrier travel

in a single tube.

Conveying tubing and bends are made from either strong, lightweight, non-corroding,

dent-resistant PVC or

optional steel, with diameters of 3", 4", or 6" And our unitized

Send/Receive Stations with built-in turbo blowers

can sit on desks or tables, or mount easily in a minimum of space on walls,

building columns, or any convenient

flat surface, without using prime plant floor space. Installation is so

easy, your own employees can set it up in less

than a day! No complicated power wiring. Just Plug the system into an existing

wall outlet. Air-Lift Carriers are

made from durable, high-density polyethylene for excellent wear in system-compatible

diameters of 3", 4", and 6",

and standard lengths of 10", 12", and 14" Their smooth surfaces

and aerodynamic design generate minimal friction,

permitting dramatic increases in system capacity and length.

Thousands of pneumatic tube system users are proving the cost efficiency

of Air-Lift Pneumatic Systems in such

diverse installations as: |

|

|

|

•

Quality Control Labs

• Factories

• Transportation Terminals

• Warehouses

• Banks

• Hospitals |

•

Auction Houses

• Auto Dealers

• Brokerage Firms

• Railroads

• Restaurants

• Motels & Hotels |

|

|

|

|

|

|

|

|

|

or

any place requiring an immediate flow of items at the lowest possible cost.

Air-Lift Pneumatic Systems

completely eliminate the need for messengers in most operations... eliminate

their wages, benefit packages, coffee

breaks, and time taken from more productive work...and deliver the goods

ten times as fast! If you're wasting

money moving things in your business, then you should look into economical,

fast, reliable, safe, and clean Air-Lift Pneumatic Systems. No other pneumatic

tube system can deliver papers, parts, or samples from one location to

another with the ease, speed, low cost, and safety of an Air-Lift system.

Basic Air-Lift System transfers items

between two similar Send/Receive Stations through a single interconnecting

tube.

For installations where limited space or building obstructions won't permit

standard 48" radius bends, 24" radius

expanded bends are available that allow the free travel of Carriers without

binding. Expanded bends can be used

for upward, downward, or horizontal runs. Two configurations of Send/Receive

Stations are available for use in the pressure/pressure Air-Lift systems,

depending on the user's station mounting requirements. The Type I Stations

suits narrow and taller mounting spaces, whereas the Type II Station fits

wider and shorter mounting locations.

Both Stations are fabricated from 16-gauge cold rolled steel with an enamel

finish. Station doors are manufactured

from heavy steel. |

|

|

|

|

|

|

|

|

Engineering

Excellence |

|

|

|

|

|

|

|

Mark

II Air-Lift is a super reliable pressure/vacuum system requiring power only

at one end of the system in a

Send/Receive station called the "Power Pedestal" that can be located

at either end of the system. The Power

Pedestal moves Carriers under pressure in one direction and under vacuum

on the return in a "push-pull" system

operation. This design allows the installation of intermediate Stations

for greater system usage and flexibility.

The special features of the Mark II System which is also designed for 3",

4", or 6" diameter Air-Lift include:

• Electrical power required only at one end of the system

• Send /Receive Station at non-powered end makes no noise whatsoever

• One or more intermediate stations that expand system usage

|

|

|

|

|

|

|

|

Safe

and Easy System Operation |

|

|

|

|

|

|

|

|

|

System

Sizes To Meet Every Need |

|

|

|

|

|

|

|

3"

Air-Lift Carriers

For loads up to 1 lb and distances to 1,000 feet. Provides 2-1/4" useful

diameter by 10" or 12" length - 26% more volume than

ordinary carriers.

4" Air-Lift Carriers

For loads up to 3 lbs and distances to 2,000 feet. Provides 3-1/4"

useful diameter by 12" or 14" length - 40% more volume than

ordinary carriers.

6" Air-Lift Carriers

For loads up to 5 lbs And distances to 1,000 feet. Provides 4-3/8"

useful diameter by 12" or 16" length - more capacity at 1/3 the

weight of ordinary carriers.

|

|

|

|

|

|

|

|

|

|

|

|

The

user simply loads a Carrier and places it in the send/receive compartment.

After closing the door, the push of a

button dispatches the Carrier immediately to its destination, simultaneously

locking the door of the receiving

Station at the other end until the air flow stops just before the Carrier

arrives. At the same time, red and white lights illuminate on the receiving

Station to indicate that a Carrier is in transit. When the Carrier arrives

at the receiving

Station, the red signal light is extinguished to indicate the Carrier's

arrival. The white signal light remains ON until

the receiving Station door is opened.

Rugged high density plastic construction assures long life for Air-Lift

Carriers. Smooth surfaces and aerodynamic

design, combined with the polished inner surfaces of extruded PVC tubing,

generate minimal friction for more system capacity and greater length than

other pneumatic tube systems commercially available.

|

|

|

|

|

|

|

|

All

of these safety and control features are standard and built into Air-Lift

Pneumatic Systems, at no extra cost.

• Exclusive electro-mechanical Safety Door Locks prevent access to

the send/receive compartments while a Station

is in process of receiving a Carrier. Fully automatic.

No user action required.

• Red signal light on receiving Station indicates system is in use;

automatically extinguished when Carrier arrives

at receiving Station.

• White signal light indicates Carrier arrival in Station; automatically

extinguished upon removal of Carrier from compartment.

Air-Lift Pneumatic Systems assure you of the finest in engineering, material,

workmanship, and service:

• Standard tubing, bend, and couplings made from strong, lightweight,

non-corroding, dent-resistant PVC.

• High-volume, low friction Carriers made from long-wearing, high density

plastic with locks and finger holds

• Wrap around station bodies fabricated from 16-gauge cold rolled steel

with scratch resistant enamel over a primed

surface to insure a permanent, hard finish.

• Station doors fabricated from heavy steel.

• Full-size rubber door gaskets resist compression-set and prevent

air leakage.

• Safety Door Lock mounted on the frame for strength.

• Acoustical foam Station interiors absorb noise and provide additional

Carrier cushioning for longer life.

• Total solid-state electronic controls mounted on a plug-in PC board

that can be replaced in minutes if necessary

• Electronic system timing for precise blower shutdown

• Industrial-quality electrical/electronic components

• Solid-State circuitry

• Industry-rated transformer

• Sprayed PC boards

• 6,000-hr. expected life

• Signal bulbs

• 30 amp terminal strip

• Color-coded wiring

• Stations shipped individually in specially designed cartons to insure

damage-free arrival

•

No Blower Mounting or Manifolding of Air

• No Expensive Three-Phase Wiring

• No Cumbersome Controls or Fittings

Your own maintenance crew or local tradesmen can install an Air-Lift Pneumatic

System in a minimum amount of

time in new or existing buildings using all factory-supplied components.

Many Air-Lift Pneumatic Systems are

used to transport samples of all types between manufacturing operations

and a quality control or test site.

Underground installation of the tubing is highly desirable in these applications,

because the tubing is protected

from the elements, from wide swings in temperature, and from accidental

damage. Utilizes heavy-wall PVC tubing

and bends for underground installation.

A unique option available on the Air-Lift Pneumatic Systems is Variable-Volume

Speed Control. Excellence has

developed this entirely new concept in point-to-point pneumatic tube systems,

that of using variable air volume to:

• Control Carrier Speed

• Reduce the force of Carrier impact upon arrival

• Reduce the noise of Carrier Impact

• Produce a smooth, non-turbulent, jolt-free transmission of the Carrier's

cargo.

Variable-Volume systems produce a smooth, gentle Carrier ride on a cushion

of air and a pillow-soft landing on the

arrival pad! The keys to this innovation in pneumatic tube systems are two

adjustable timers. A pneumatic tube

system requires the most air pressure to lift the Carrier out of the Station

and through its initial vertical rise. But,

once the Carrier is level, the system's power requirements drop significantly

to just enough pressure to overcome

any friction between the Carrier and the tubing walls.

Variable-Volume Carrier Speed Controls are standard in 6" systems,

and available at nominal cost in 3" and 4"

systems Another design for carrier slowdown is a relief valve, triggered

by air pressure, that controls the Carrier as

it reaches the point of final decent into the terminal Station. This valve

vents system pressure and allows the

Carrier to fall unpowered into the Station. To counteract the pull of gravity,

a second valve simultaneously builds

up back pressure to cushion the Carrier's fall to a soft and gentle landing

on the arrival pad. The total result is a

cargo that rides smoothly and arrives unshaken.

In addition to the standard sound-absorbing special gaskets and foam Carrier

arrival pads used in all Air-Lift

Send/Receive Stations to dampen noise-producing vibration and Carrier impact

shock, offers the user a choice of

different options that can greatly eliminate the blower noise inherent in

pneumatic tube systems:

• A remote blower that restricts all blower noise to a location where

sound is not objectionable

• For installations where condensation of moisture particles in the

air flow can cause a problem, an outside air

intake can be incorporated into an Air-Lift Pneumatic

System to provide a moisture-free atmosphere

• Telescoping expansion joints for long, straight runs in variable-temperature

conditions.

• Fire dampers - guillotine type - when tubing must penetrate fire

walls or floors.

• Air-Lift Pneumatic Dispatch Systems can be customized to meet your

requirements.

• Stainless steel Send/Receive Stations for food processors, medical

facilities, and laboratories

• Galvanized steel Send/Receive Stations for highly-corrosive environments,

such as paper mills and chemical

plants

• Downsend available on all models Send/Receive Stations with double

doors and controls for access from both

sides of walls or windows between offices.

• Special paint finished to match your color scheme

• Extra-long Carriers for blueprints, photo plates, x-ray films

• Static-free Carrier linings for transporting electronic components

or photographic materials

• Inexpensive between floors system that uses gravity to drop carriers

and pressure only for return

• Clear, high-impact plastic doors

• Steel tubing systems available in 2-1/4", 3", 4",

4-1/2" and 6" round, and 4"x7" oval |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

|

Mini-Mark

II System-Pressure/Vacuum |

|

|

|

|

|

|

|

Includes

two (2) stations, (2) 90 degree bends, four (4) carriers, 100 feet of straight

tubing and hardware, and

120 feet of wire. |

|

Basic |

3" |

4" |

6" |

|

|

|

6 Cond. Wire per ft. |

|

|

|

|

|

|

|

|

|

|

System

Additions Prices |

|

|

Description |

3" |

4" |

6" |

Tubing |

10

feet-heavy duty - includes couplings |

|

|

|

Bends |

24"

Centerline Expanded 90° Bend |

- |

|

- |

24"

Centerline Expanded 90° Bend Heavy Duty |

|

- |

- |

36"

Centerline Expanded 90° Bend Heavy Duty |

- |

- |

|

48"

Centerline Standard 11° Bend |

- |

|

- |

48"

Centerline Standard 11° Bend Heavy Duty |

|

|

- |

48"

Centerline Standard 22° Bend |

- |

|

- |

48"

Centerline Standard 22° Bend Heavy Duty |

|

|

|

48"

Centerline Standard 45° Bend |

- |

|

- |

48"

Centerline Standard 45° Bend Heavy Duty |

|

|

|

48"

Centerline Expanded 90° Bend |

- |

|

- |

48"

Centerline Expanded 90° Bend Heavy Duty |

|

|

|

Couplings |

PVC |

- |

|

|

PVC

Heavy Duty |

|

- |

- |

Stainless

Steel (No - Hubs) |

|

|

|

Air

Line Elbow (remote air or remote blower) |

|

|

|

Carriers |

9"

Inside Length |

|

- |

- |

12"

Inside Length |

|

|

|

14"

Inside Length |

- |

|

- |

|

|

|

Air-Lift System, Air Conveyor,

Air Lift Conveyor Systems, Air Tube Systems, Pneumatic Dispatch System,

Pneumatic

Tube System, Air-Lift Pneumatic System, Air Operated Conveyor, and Air

Pneumatic Conveyor System from your source

for material handling equipment. |

Back to Product Category

|