|

DUAL

MAST MEZZANINE LIFT

|

|

VRC

|

|

Dual Mast Mezzanine Lift (Vertical Reciprocating Conveyor) provides

extra strength for heavy loads up to 12,000 pounds and offers

a variety

of larger platform carriage sizes up to 12' x 12'. This lift

is great when

overhead space is limited because it only requires 7'2"

of height above

the upper level. Also, it can be loaded and unloaded from the

front or

the rear. |

|

|

|

|

|

| Made

Especially For... |

|

Warehousing/Storage

Facilities, Manufacturing Facilities, Paper and

Textile Industries, Aerospace Industry, Military Bases, Ships

and

Marine Vessels to name a few. |

|

|

|

|

| Standard

Features... |

|

|

•

Travel Height: Up to 90'

• Operating Speed: 30 fpm

• Power Requirement: 230v 3-phase 60 hertz

• Operator controls at each level

• Upper and Lower Travel Limit Switches

• Fail-Safe Brake Motors

• Chain Safety Brakes

• Slack Chain Switches

• Soft Start/Soft Stop Operation

• Mount: Surface or Pit |

|

|

|

|

|

|

For

Heavy Loads In Height

Restricted Areas

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Options

|

|

|

Technical

Specifications |

Operating

Speed Increased

Power - 460v 3-phase 60 hertz Ground Level Loading Ramp

Security Enclosures

Gates with Electro -

Mechanical Interlocks

Multi - Level Operation

Special Environments |

|

Technical

Specifications for the Dual

Mast Mezzanine Lift are shown below.

Please fill in your desired specifications

in the spaces provided. Contact us for

special requirements or configurations.

|

|

|

|

1.

What weight capacity do you require?

(1,000 - 12,000 lbs.) _____________ |

|

2.

What is the height in inches from the

ground level floor surface to the

second level floor surface?

(Up to 90') __________________ |

|

|

|

Platform

Carriage Side

Rails Enclosures

|

|

3.

Platform carriage size:

4' - 12' (w) x 4' - 12' (d) ___________ |

|

4. What

platform load height do you

require? 72"(h) standard; 78"(h)

max.

through doors. _______________

|

|

48"(h)

on non-access openings,

snap chains on access ends

|

|

|

5.

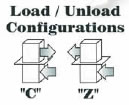

Which load / unload configuration

do you require? ____ C _____Z |

|

|

|

|

|

6.

How will the unit be mounted?

___surface ___ pit |

|

|

|

Surface

Mount: |

|

The

loading height is 6"-8" from the floor

on the ground level and flush with the

floor on the upper levels. |

|

|

|

|

|

|

|

Pit

Mount: |

|

|

Loading

height is flush with the floor on

all levels. (Standard Dual Mast Pit Depth

is 6" - 8".) |

|

|

|

| Note: |

|

|

|

Our

mezzanine lifts are manufactured to ANSI/ASME B20.1 safety standards.

They are not subject to elevator codes as they are

designed for material lifting only. No personnel are permitted

to ride on any mezzanine lift. The following items are to be

supplied by

others and are not included with the mezzanine lift: (1) Wall

and floor hardware to secure the lift to the walls and floor,

(2) External

electrical wiring which is to be performed by a qualified electrician

to local and national codes, (3) Conduit and disconnect switch

that is required to connect to our control panel, (4) Upper

and lower thresholds. |

|

|

|

|

|

|

|

|

|

|

|

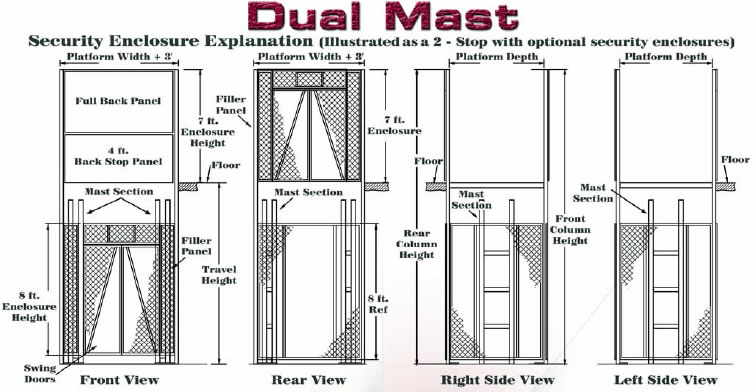

Illustrated

As A 2-Level Lift with

Optional Security Enclosures;

Multi-Level Versions are Available |

|

|

|

|

|

|

ARCHITECTURAL

SPECIFICATIONS

VERTICAL RECIPROCATING CONVEYOR

|

|

|

|

|

|

| PART

1: GENERAL |

|

|

|

|

|

|

| 1.01:

OVERVIEW |

|

|

A. Design and manufacturing of one (1) dual mast type Vertical

Reciprocating Conveyor (VRC) including

mechanical drive unit, operator controls,

safety gates and enclosures as shown on project drawings and

as specified herein. |

|

|

|

|

|

| 1.02:

REFERENCES |

|

|

|

|

|

|

|

|

A.

ANSI - American National Standards Institute (ANSI B20.1) |

|

B.

ASME - American Society of Mechanical Engineers (ASME B20.1) |

|

C.

NEMA - National Electrical Manufacturer's Association |

|

|

|

|

|

| 1.03:

SUBMITTALS |

|

|

|

|

|

|

|

|

A.

Product Data: Submit latest edition of Dual Mast VRC datasheet

and general drawings with the proposal. |

|

|

|

|

|

|

B.

Customer Drawings: |

|

|

|

|

|

|

|

1.

Submit Customer Engineering Drawings for customer approval within

2 weeks after receipt of an order to

include plans, elevations, sections of the VRC, base plate and

lateral loading values, and recommended pit

dimensions if applicable. |

|

|

|

|

|

|

|

2.

Submit VRC Specification Sheet for approval within two weeks

of receipt of an order to include scope

of work, operating and control voltages, lift speed, type of

finish, and any special project notes. |

|

|

|

|

|

|

C.

Closeout Submittals provided with VRC Equipment: |

|

|

|

|

|

|

|

1.

Electrical Schematics Drawing including control panel layout

and Bill of Material reflecting original

manufactured part numbers. |

|

|

2.

Mechanical Installation Manual and Electrical Installation Guide. |

|

|

3.

Digital Control Panel trouble shooting guide. |

|

|

4.

Owner's Manual including replacement parts list, exploded parts

drawings, operating instructions,

maintenance schedule, and service and troubleshooting guidelines. |

|

|

|

|

|

| 1.04:

QUALITY ASSURANCE |

|

|

|

|

|

|

|

|

A.

Manufacturer must have a minimum of five (5) years experience

in the manufacturing of vertical

reciprocating conveyors. |

|

B.

Vertical Reciprocating Conveyors (VRC) are covered by ANSI/ASME

B20.1 Safety Standards for Conveyors.

We have thousands of vertical lifts installed throughout the

country and in surrounding countries. NO VRC has ever

been shut down due to lack of elevator code compliance. |

|

C.

Installer must have the approval of FSI and have a minimum of

five (5) years experience in the installation

of vertical material lifts. |

|

|

|

|

|

| 1.05:

WARRANTY |

|

|

|

|

|

|

|

|

A.

The manufacturer shall warrant the VRC against manufacturing

defects from date of installation as outlined

below: |

|

|

|

|

|

|

|

1.

Electric Motor and Cyclo-Drive Reducer - two (2) years. |

|

|

2.

Electrical Components - ninety (90) days. |

|

|

3.

Mechanical Components - one (1) year. |

|

|

|

|

|

| PART

2: PRODUCTS |

|

|

|

|

|

|

|

2.01:

VRC MECHANICAL SPECIFICATIONS |

|

|

|

|

|

|

|

A.

Load Capacity: The VRC shall be rated at a live load capacity

of _______ lbs. |

|

|

B.

Operating Speed: The VRC shall have a vertical lifting speed

of 20 - 25 feet per minute when loaded to

maximum capacity. |

|

|

C.

Vertical Travel Height: The VRC shall have a vertical lifting

height of _____ inches with a total of _____

landings (including lowest level) with a distance between floors

of ______ inches. |

|

|

D.

Lift Carriage: The VRC carriage shall be a minimum of _____

inches wide x _____ inches deep

with a steel deck plate and minimum of 48" high welded

or bolt-on side panels on all non-operating ends

and safety chains with snap hooks on all operating ends. |

|

|

E.

Vertical Masts: The VRC shall have a two (2) support mast constructed

of four (4) 4" square structural grade

steel tubes for vertical support and strengthened by horizontal

2" square steel tubes. |

|

|

F.

Deflection Under Load: No portion of the VRC shall exhibit permanent

deflection when loaded to full capacity. |

|

|

G.

Shock Load: The VRC must be able to withstand a shock load of

at least 500% to ensure safety. |

|

|

H.

Lifting Means: The drive system shall be comprised of four (4)

sprockets transmitting lifting forces through

four (4) chains to the back section of the carriage. The electrical

drive motors shall be 100% duty cycle coupled

with a Cyclo-Drive gear reducer with a shock load rating of

500%. Planetary or helical gear reducers are not

allowed. |

|

|

I.

Safety Brakes and Devices: The Carriage shall be equipped with

one (2) broken/slack chain brake that

prevents the carriage from descending more than 6" if tension

is lost on either chain. Slack chain switches are

required to disable motor power in the event a chain becomes

slack or broken. |

|

|

J.

Security Enclosures: Guarding on all non-operating sides of

the VRC shall be by security enclosures extending

a minimum of 8' high at each level consisting of expanded metal

which will reject a ½" diameter ball. Security

enclosures shall tie directly into the vertical mast for added

structural support. |

|

|

K.

Landing Gates: Gates are required on all operating sides of

the VRC at each level of operation. |

|

|

|

1.

The gates shall be (double swing) (vertical slide) (horizontal

slide) (roll-up) type. |

|

|

|

2.

Each gate must be equipped with an elevator approved electro-mechanical

interlock to prevent opening

of the gate unless the carriage is present and to prevent operation

unless all gates are closed. |

|

|

L.

Signage: Signs dictating "NO RIDERS" and maximum weight

capacity shall be placed at every access point

and visible from all operating ends of the carriage. |

|

|

M.

Approach Ramp: If pit mounting is not specified, the manufacturer

shall supply a steel fabricated 8" high

approach ramp to be installed within ½" of the VRC

carriage at the ground level. |

|

|

N.

Power Requirements: The VRC shall be manufactured to operate

on 230 volts / 3 phase / 60 hertz power.

Controls voltage must be no greater than 24 volts. |

|

|

O.

Load Pattern: The pattern for loading and unloading the carriage

at different levels must be a "Z" or "C"

configuration. |

|

|

|

|

|

| 2.03:

VRC ELECTRICAL SPECIFICATIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

A.

Electric Motor: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Each of two (2) motors shall have a minimum duty cycle of

100%. |

|

|

|

2.

Each motor and Cyclo-Drive gear reducer must be able to withstand

a shock load of at least 500% to ensure

safety. |

|

|

|

3. Motor horsepower shall be sized to handle the carriage weight

in addition to the rated live load and

specified speed. |

|

|

|

4.

All motors are three phase and shall be designed for continuous

duty at ambient temperatures for 32° to 102°

Fahrenheit |

|

|

|

5.

The motors shall not automatically restart when the overload

device is reset. |

|

|

|

6.

Each motor shall be equipped with a heavy-duty, long life, fast-acting

fail-safe disc brake to ensure the brake

will hold in case of power failure. |

|

|

|

|

|

|

|

|

|

|

|

|

B.

Controls: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.

Each operating floor shall be equipped with a momentary contact

push-button control station with full call,

send and mushroom style E-stop switches for manual control of

lift operation. |

|

|

|

2.

An internally pre-wired, NEMA 12 rated Intelitroll self-diagnostic

control panel shall be provided with

appropriate transformer, overload relay, phase monitor device,

field wiring terminal block and breakers. |

|

|

|

3.

Limit Switches: The VRC shall be equipped with a floor level

switch at each level, upper level, and over

travel limit switch to provide precise positioning of the carriage. |

|

|

|

4.

Slack Chain Safety Switches: Two switches shall be provided

to monitor slack chain situations and disable

power to the motor while engaging carriage safety brakes in

the event of a slack or broken chain. |

|

|

|

5. The control voltage shall not exceed 24 volts for safety

reasons. |

|

|

|

|

|

|

|

|

|

|

|

|

C.

Power Source: Owner shall terminate high voltage operating power

within 10 feet of the location designated

for the VRC installation. |

|

|

|

|

|

|

|

|

|

|

| 2.04:

FINISHES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A.

All carbon steel surfaces shall be coated with an industrial

enamel finish - color slate gray and black. |

|

|

B.

Prior to applying finish, all dirt, mill scale, oil and grease

shall be removed from carbon steel surfaces

by a combination of brushing, wiping and use of solvents. |

|

|

|

|

|

|

|

|

|

|

|

PART

3: EXECUTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.01:

EXAMINATION |

|

|

|

|

|

|

|

A.

Prior to commencing installation of the VRC, the installer shall

visually examine the conditions under which

the VRC is to be installed and notify the architect in writing

of conditions detrimental to the proper and timely

completion of the work. |

|

|

|

|

|

|

|

|

|

|

|

3.02:

INSTALLATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A.

Installer must comply with manufacturer's detailed mechanical

and electrical installation instructions for proper

installation and to meet safety codes. All thresholds and extra

installation materials needed must be supplied

by the installer. |

|

|

|

|

|

|

|

|

|

|

| 3.03:

FIELD QUALITY CONTROL |

|

|

|

|

|

A.

Inspection: Upon completion of installation, the VRC shall be

inspected to verify that it meets all

requirements set forth by FSI and Parts 1, 2 and 3 of this Section. |

|

|

|

|

|

|

|

|

|

|

|

|

B.

Tests: |

|

|

|

1.

Operating Load Test: The owner will provide a _______ pound

test load and load the VRC at the lowest

level. The loaded VRC carriage shall be conveyed to an upper

floor level and returned to the lowest level to

assure proper operation. If the VRC cannot lift or lower the

load, the VRC shall fail the test. |

|

|

|

2.

Performance Test: This test is to be performed in conjunction

with Test 1 above. During the demonstration

of the lifting and lowering test, the owner shall measure the

time required to lift and lower the capacity load.

The owner will average times for lifting and lowering the load

and calculate the average feet per minute travel

speed. If the VRC does not lift the load within 10% of the specified

speed, or if the lowering speed exceeds

the lifting speed by more than 10%, the VRC shall fail the test. |

|

|

|

3.

Stationary Load Test: This test is to be performed in conjunction

with Test 1 above. The loaded VRC

carriage shall remain stationary at an upper level for a minimum

of one (1) hour. After the one (1) hour period,

the VRC will be inspected for deflection of the components or

drift of the platform. If deformation or downward

drift is evident, the VRC shall fail the test. |

|

|

|

|

|

|

|

|

|

|

|

3.04:

ADJUSTING AND CLEANUP |

|

|

|

|

A.

Installer shall touch up all scratches, abrasions, and other

defects in the pre-finished surfaces with the same

material color and type of finish as that used at time of fabrication. |

|

|

B.

Installer will remove and dispose of all rubbish and debris

caused by the work under this section. |

|

|

C.

Verification that equipment is properly installed in accordance

with manufacturer's guidelines and guarded to

meet or exceed ANSI/ASME B20.1 Safety Standards for Conveyors. |

|

Dual

Mast Mezzanine Lift, Mezzanine Material Lifts, Custom Industrial

Material Lift, Vertical Conveyor, Freight Elevator,

Vertical Material Lifts, Vertical Platform Lifts, Vertical Reciprocating

Conveyor, Pallet Master, and VRC form your

source for material handling equipment. |

|