Back to Product Category

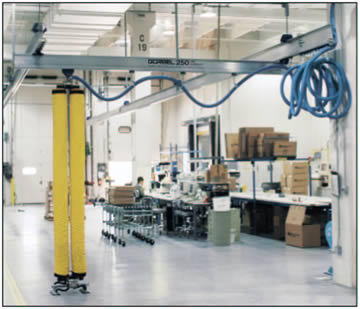

Ceiling

Mounted Bridge

Cranes & Monorails |

|

|

|

|

|

| The

safe, productive, ergonomic solution for overhead materials handling operations. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pricing

and Dimensional Specifications -

Click a Load Capacity Link Here > |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

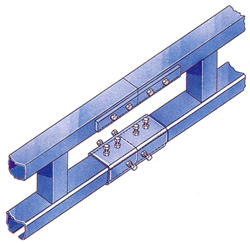

Rigid

Runways Provide for Superior

Positioning of Loads |

|

Calculating

Applied Forces to the

Supporting Structure |

|

|

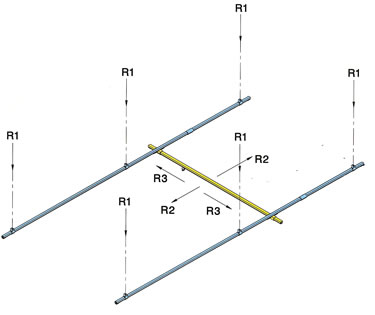

This

illustration shows the relative position and the

direction of forces that a ceiling-mounted bridge crane

applies to its supporting structure. Before installing any

crane system, it’s critical that you determine whether

your building will safely support the loads. |

Work Station Bridge Cranes

are installed so that

the runways are rigid. They do not move laterally

or longitudinally. In addition, the floating end

trucks with horizontal wheels prevent binding. The

combination of these design features results in

unmatched ease of positioning and ease of movement.

The bridge travels smoothly down the runways, and

movement is unvarying along the way, no matter

where a load is positioned on the bridge. This allows

superior load positioning. |

|

|

Loads

applied to the support structure can be

determined using the following formulas, where: |

|

|

|

|

|

|

|

|

|

|

Another

advantage of rigid runways is that they can

be reinforced (trussed “S" series), so they are useful

where long spans are required. This eliminates the

need for expensive intermediate support stringers,

and it lowers overall installation cost. |

|

|

|

| Mixed

Capacity Bridge Crane Systems: |

|

|

|

Reduced

bridge dead weight equals better

ergonomic solutions. |

|

|

|

Mixed-capacity

systems allow multiple lower capacity

bridges to be used on higher capacity runways, provided

the equivalent center loads (ECL) are verified at the

factory to ensure that runways and hangers are not

overloaded. For example, using mixed-capacity end

trucks, four 500 lb. bridges (utilizing 500 series rail)

can be hung from a 2000 lb. runway, allowing side-by-

side use of all four bridges without overloading the

system. By mixing bridges of various sizes and capacities,

mixed-capacity systems offer reduced bridge

dead weight, easier movement, and reduced cost. |

|

|

|

|

|

|

|

|

R1

= vertical load applied by support hanger (lb.) |

|

R2

= longitudinal load applied by movement of the

crane to each runway (lb.) |

|

R3

= lateral force applied by movement of the trolley

and load to each runway (lb.) |

|

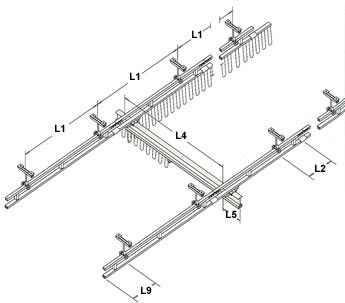

L1

= distance between support centers (ft.) |

|

|

(NOTE:

If there are only 2 supports/runway,

L1= L1 x 0.5) |

| What

is meant by Rated Capacity? |

|

|

|

The

rated capacity is the live load that can be lifted

by the crane system. The design load for the crane

system is based on the rated capacity plus 15% for

the weight of the hoist and trolley (capacity x 1.15)

and an additional 25% for impact (capacity x 1.25)

for a total design of capacity x 1.4 (Note, 25% impact

factor is good for hoist speeds up to 50 f.p.m.). For

example, a 1000 lb. Crane allows you to pick

up a 1000 lb. load, provided the hoist weighs 150 lb.

or less and the hoist speed is less than 50 feet per

minute. |

|

|

L4

= bridge span: center line distance between

runways (ft.) |

|

P

= live load capacity (lb.) |

|

1.4

= design factor (see description below) which

includes 25% for impact and 15% for assumed hoist

and trolley weight |

|

W

= weight per foot of runway (lb./ft.) See installation

guide below |

|

w

= weight per foot of bridge (lb./ft.) See installation

guide below |

|

R1

= 1.4 x P + (W x L1) + (w x L4) |

|

|

Design

load for deflection calculations is based on the

rated capacity plus 15% for the weight of the hoist and

trolley (capacity x 1.15). Under no conditions should the

crane be loaded beyond its rated capacity. Gorbel Work

Station Cranes meet or exceed the ANSI B30.11

specifications for underhung bridge cranes. |

|

|

|

|

|

2 |

|

|

R2

= ((1.15 x P) + (w x L4) )x .10 |

|

|

2 |

|

|

|

|

R3

= 1.15 x P x .20 |

|

|

|

|

|

|

|

WARNING: Equipment described in this brochure is not

designed for, and should not be used for, lifting, supporting,

or transporting humans. Failure to comply with any one of the

limitations noted can result in serious bodily injury and/or

property damage. |

|

|

Pricing

and Dimensional Specifications -

Click a Load Capacity Link Here > |

|

|

|

|

|

|

|

|

|

|

| |

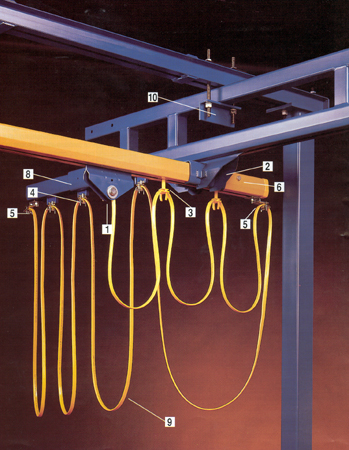

Anatomy

of a Work Station Crane |

|

|

|

|

|

|

|

|

|

|

|

|

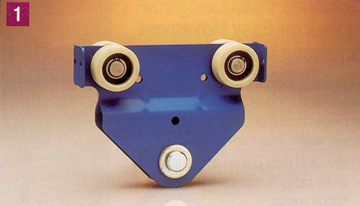

1 |

|

HOIST

TROLLEYS |

|

Hoist

trolleys provide the connection between the lifting

device and the monorail. The trolleys are designed for

effortless movement along the track. The stamped body

fits most rigid hook or eye lifting devices. |

|

|

•

Wheels are tapered to match the 2° taper of the track.

This reduces rolling resistance and wheel wear. Wheels

contain ball bearings that are sealed and lubricated for

life.

• Trolleys are designed to operate in temperatures from

+5° F to +200° F.

• All trolleys meet or exceed the ANSI B30.11

specification for underhung bridge cranes. |

|

|

|

|

|

|

|

|

|

|

|

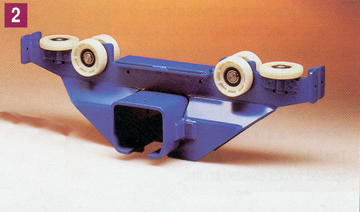

2 |

|

END

TRUCKS |

|

|

End

trucks provide the connection between the bridge

and runways. They are designed for effortless movement

along the runway.

• Wheels are tapered to match the 2° taper of the track,

which reduces rolling resistance and wheel wear.

Wheels contain ball bearings that are sealed and

lubricated for life.

• Two horizontal wheels center the end truck within the

runway which prevents binding of the bridge. As a

result, the position of the load on the bridge has little

effect on the amount of force needed to move the

bridge along the runway.

• Any slight runway track misalignment is taken up by the

bridge floating in one end truck, while the other end

truck is firmly clamped to the bridge.

• All end trucks meet or exceed the ANSI B30.11

specification for underhung bridge cranes. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

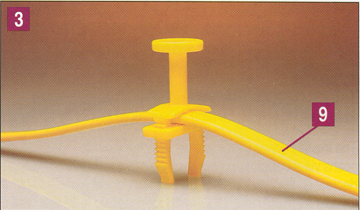

3 |

|

FESTOON

GLIDES |

|

Festoon

gliders are used to support flat cable along the

monorail, and they are standard on monorails of 63 feet

or less. No tools are required to attach the festooning to

the gliders. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

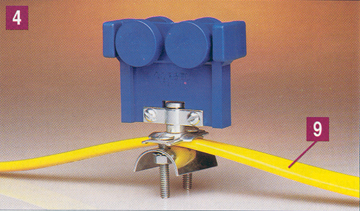

4 |

|

FESTOON

TROLLEYS |

|

Festoon

trolleys (optional) are used to support flat cable

or air hose along the monorail. The trolleys have four

wheels and a pivoting festoon saddle support. They are

ideally suited for long runways (greater than 63 feet) or

with round cable or air hose. With monorails greater than

63 feet or with an all aluminum system, festoon trolleys

are standard. Special festoon trolleys for vacuum hose

are also available. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

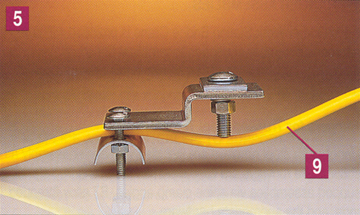

5 |

|

FESTOON

CLAMPS |

|

|

Festoon

clamps anchor the festooning at the start of the

monorail. They also prevent the festoon gliders from

exiting the track and they can provide a redundant stop

of the trolley. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

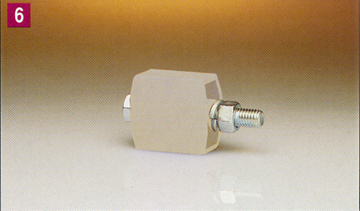

6 |

|

END

STOP BUMPERS |

|

|

High-impact

molded end stop bumpers are provided on

all monorails, to prevent the trolley from exiting the

track. The bumpers are bolted to the track to physically

limit the travel of the trolley. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

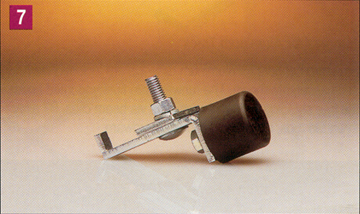

7 |

|

UNIVERSAL

BUMPERS |

|

A

universal bumper can be used as a secondary end

stop, either internally or externally. |

|

|

|

|

|

|

|

|

|

|

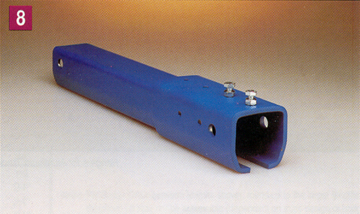

|

8 |

|

STACK

SECTIONS |

|

|

A

stack section at one end of a monorail serves as an

extension that allows festoon carriers to be stored on the

end of the monorail without reducing hoist coverage. |

|

|

|

|

|

|

|

9 |

|

FLAT

CABLE AND/OR AIR HOSE |

|

A

flat cable festooning system is included in all

monorails. Plenty of cable is provided for 3 foot loops

on the monorail.

Optional air hose is also available and is supported by

optional festoon trolleys. |

|

|

|

|

|

Optional

air hose is also available and is supported by

optional festoon trolleys. Work Station Cranes can utilize

optional conductor bar electrification, but this results in

an increase up to 40% of the amount of effort required

to move the system. |

|

|

|

|

|

|

|

|

|

10 |

|

HANGER

ASSEMBLIES |

|

Each

Work Station Bridge Crane or monorail is

provided with the number of standard hanger

assemblies listed, based on the maximum “L1” spacing

shown in this brochure. Sway bracing is required on all

systems, except flush-mounted systems. Sway bracing

kits are not included in the crane kit (see Sway Brace

Fitting caption on this page). |

|

|

|

|

|

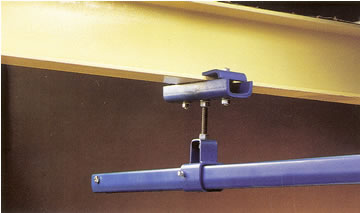

Standard

Hangers for Plain Steel Track |

|

Standard

hangers for plain steel track, with a 20 inch

threaded rod (B7 alloy), are included with each assembly.

The threaded rod can be field cut to custom lengths as

required. An optional 72 inch rod can also be supplied.

Two beam clips are bolted to the upper hanger bracket

and are clamped to the supporting structure. The upper

hanger brackets are adjustable for flange widths from

1 to 10 inches. |

Standard

Hanger - Plain Steel Track |

|

|

|

|

|

|

|

|

|

|

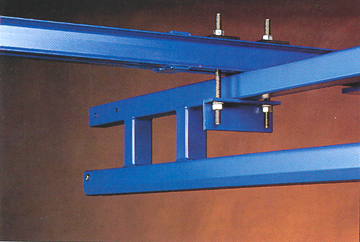

Hangers

for Trussed Steel Track

Hangers for

steel runways are included with each

assembly as shown. The runways are flush mounted

under the free standing support assemblies via spine

clamp angles, B7 alloy threaded rods, and the appropriate hardware. |

|

|

|

|

Standard

Hanger - Trussed Steel Track |

|

|

|

|

|

|

|

|

|

|

|

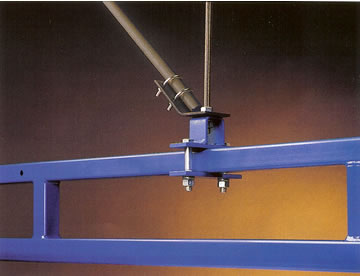

Sway

Bracing Fitting

(not supplied as standard) |

|

|

|

|

|

Sway

bracing is required on all systems except flush

mounted systems to provide for a rigid-mount runway

that allows the end truck to move freely. The fittings

permit easy sway bracing with 1 inch standard steel pipe

(pipe supplied by others). The flange is drilled to accept

a 5/8 inch bolt (bolt by others) with two U-bolts

(furnished). These optional fittings are not supplied

as standard with crane kits. |

|

|

|

|

Sway

Bracing Fitting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPLICE

JOINTS FOR STEEL TRACK |

|

|

|

|

|

A splice joint

is used to join track sections together

and enable the installer to quickly and properly align

the joined sections of track. Adjusting bolts are

provided on the splice joint for leveling and aligning. |

|

|

|

| |

|

|

|

|

INSTALLATION

GUIDELINES |

|

|

|

|

| Pricing

and Dimensional Specifications - Click a Load Capacity Link Here |

|

|

|

|

| CAPACITY |

SERIES |

WEIGHT

PER

FOOT |

MAX.

L1 |

MAX.

L2 |

MAX.

L5 |

MAX.

L9 |

250# |

GLC |

2.55 # |

6’ |

8’’ |

18’’ |

18’’ |

| GLCS |

4.88 # |

20’ |

48’’ |

18’’ |

48’’ |

| GLCSL |

8.14 # |

25’ |

48’’ |

18’’ |

48’’ |

500# |

GLC |

4.11 # |

6’ |

8’’ |

24’’ |

20’’ |

| GLCS |

7.23 # |

20’ |

48’’ |

24’’ |

48’’ |

| GLCSL |

10.94 # |

25’ |

48’’ |

24’’ |

48’’ |

| GLCSLX |

11.26 # |

30’ |

48’’ |

24’’ |

48’’ |

1000# |

GLC |

6.50 # |

6’ |

8’’ |

24’’ |

20’’ |

| GLCS |

12.09 # |

20’ |

48’’ |

24’’ |

48’’ |

| GLCSL |

13.37 # |

25’ |

48’’ |

24’’ |

48’’ |

| GLCSLX |

15.31 # |

30’ |

48’’ |

24’’ |

48’’ |

2000# |

GLC |

9.00 # |

6’ |

8’’ |

24’’ |

24’’ |

| GLCS |

14.59 # |

20’ |

48’’ |

24’’ |

48’’ |

| GLCSL |

20.14 # |

25’ |

48’’ |

24’’ |

48’’ |

| GLCSLX |

20.95 # |

30’ |

48’’ |

24’’ |

48’’ |

4000# |

GLC |

9.00 # |

6’ |

8’’ |

24’’ |

24’’ |

| GLCS |

18.42 # |

20’ |

48’’ |

24’’ |

48’’ |

| GLCSL |

23.83 # |

25’ |

48’’ |

24’’ |

48’’ |

| GLCSLX |

28.02 # |

30’ |

48’’ |

24’’ |

48’’ |

|

|

|

|

|

|

L

1 = |

MAXIMUM

HANGER

CENTERLINE |

|

|

|

|

Maximum Hanger

Centerline is

considered from the center of a hanger

to the center of the neighboring

hanger. |

|

|

|

| Note: |

Anti-kick-up

end trucks* are required for the following:

bridges with < 8' span (L4) and a bridge

cantilever (L5) > 12"

bridges with < 10' span (L4) and a bridge

cantilever (L5) > 15"

bridges with < 15' span (L4) and a bridge

cantilever (L5) > 18" |

|

|

|

L

2 = |

SPLICE

JOINT CENTERLINE

TO HANGER CENTERLINE

Splice Joint Centerline to Hanger

Centerline is considered from

center of a splice joint to the center of

the nearest support hanger. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L

5 = |

BRIDGE

CANTILEVER**

Bridge Cantilever is considered from

the centerline of the runway to the end

of the bridge (see table and notes). |

*

Anti-kick-up end trucks are not included as part

of the standard crane kits. |

|

|

|

|

|

|

|

|

|

|

|

|

|

**2000#

@ 10' span (L4) and bridge cantilever (L5)

15" need anti-kick-up end trucks.

Consult us for information on bridges greater

than 15' span (L4). |

|

|

|

|

|

|

|

|

|

|

|

L

9 = |

MAXIMUM

RUNWAY

CANTILEVER

Runway Cantilever is considered from

the center of the end support assembly

to the end of the runway. |

|

|

|

|

|

|

|

|

|

|

|

STANDARD BRIDGE CANTILEVER |

Bridge

Series |

Bridge Overall Length |

| Steel |

| <=23' |

28' |

29' |

33' |

34' |

| 250 |

12" |

18" |

24" |

NA |

NA |

| 500 |

12" |

18" |

24" |

18" |

24" |

| 1000 |

12" |

18" |

24" |

18" |

24" |

| 2000 |

12" |

18" |

24" |

18" |

24" |

| 4000 |

15" |

18" |

24" |

18" |

24" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: |

Same

guidelines apply for Monorails

(GLMS,GLMSL,GLMSLX, ALM),

with the exception of the "L5" dimension

(not applicable). |

|

|

|

|

|

|

|

Note: |

Typical

L5 is 12". Max. L5 may not be

achievable (dependent on truss design

of bridge.) |

|

|

|

|

|

|

|

|

|

|

|

|

Bridge Cranes, Cranes, Ceiling

Mounted Bridge Cranes & Monorails, Enclosed Track Design, Overhead

Bridge Cranes, Hoist,

Top Running Bridge Cranes, and Under Running Crane from your source for

material handling equipment. |

Back to Product Category

|