Back to Product Category

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

PRICES

FOR THE MANUAL POWERSTOP VEHICLE RESTRAINT |

| Model |

Weight |

Price |

| Powerstop

(M) |

310# |

|

| Powerstop

(manual restraint, manual lights) (MML) |

340# |

|

| Powerstop

(manual restraint, automatic lights) (MAL) |

375# |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

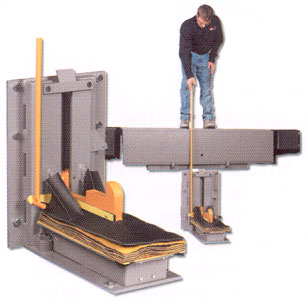

Simple

and Reliable Performance |

Three

Manual PowerStop

Communication Systems |

|

Mechanical

activation of the PowerStop® M Series

Restraint is easy. The dock attendant simply lifts up

on the release lever with the operating bar after the

truck is parked against the dock bumpers. The re-

straint is easily observed capturing the Rear Impact

Guard (RIG). During the loading process, the spring

loaded restraint arm floats freely with the trailer. |

|

PowerStop-M

PowerStop-

MML

PowerStop-

MAL |

-

restraint and communication signage

only

- Restraint, communication signage and

manually switch operated lights

- Restraint, communication signage and

automatically switching lights. |

|

|

|

|

|

|

|

|

|

|

|

|

| Low

Maintenance Design |

Effective

Communication |

|

A

stationary mount design means less maintenance

which can limit potential damage throughout the life of

the PowerStop. The PowerStop is quickly and easily

stored by pushing down on the restraint arm assembly

with the operating bar |

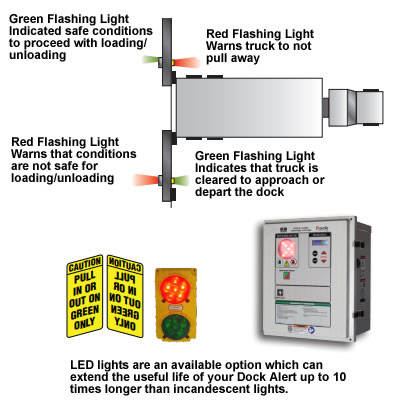

The

inside control panel and exterior compact

light package incorporate instinctive red and green

signals which work in opposing modes. A green light

outside guides a backing truck into the dock position

while a red light inside warns the dock attendant that

loading/unloading conditions are not safe. Once the

PowerStop has secured the vehicle, the lights will

switch to green inside and red outside, informing

the truck driver to not move and indicating a safe

condition for the dock attendant. |

|

|

|

|

|

|

|

|

|

|

Specification |

|

|

|

|

|

|

| GENERAL

DESCRIPTION: |

PowerStop-MAL

- PowerStop-MAL with Automatic |

|

| All

Manual PowerStop (PowerStop-M) vehicle restraints |

Dock

Alert Communication System. Adding the

automatic Dock Alert communication system to the

PowerStop-M establishes a clear line of communication

between truck drivers and dock personnel. During

normal operation the control panel switch is in the “On”

position. When the restraint arm is in the stored position,

the exterior light will flash green indicating the truck is

clear to approach or depart the dock while the interior

light flashed red warning the dock attendant conditions

are not safe for loading/unloading. Once the restraint has

been activated, and the dock attendant confirms the

restraint arm has engaged the RIG, the Dock Alert will

automatically change light signal conditions. Now the

exterior light flashed red warning the driver not to pull

away, while the interior light flashes green indicating safe

conditions and to proceed with the loading/unloading.

In the “By-Pass” position, the system will override the

automatic feature providing a flashing red light on the

exterior and a flashing green on the interior. |

|

are

designed to secure a cargo trailer’s Rear Impact

Guard (RIG) to reduce the likelihood of premature

trailer separation during the loading/unloading process.

The exclusive PowerStop vehicle restraint features a

complete mechanical restraint mechanism, activation

rod and storage bracket, along with communication

signage. An optional Dock Alert Communication

System, including inside control panel and exterior

communication lights, is also available. |

|

|

|

|

| CONSTRUCTION: |

|

The

PowerStop-M restraint system is designed to be a

stationary mount, non-impact device, permanently

mounted to loading dock foundation or drive approach.

Restraint shall be preserved in a non-corrosive powder-

coated finish with plated hardware. Restraint arm shall

be protected by a bellows style cover to eliminate the

accumulation of debris. Once activated, the PowerStop-

M extends upward to the RIG. The uniquely designed

dual locking restraint arm minimizes “trailer creep”,

securing the trailer with over 30,000 lb. (average) of

pull-out force. The PowerStop-M is affordable and

easy to install. It is ideal for all manufacturing,

warehouse and distribution applications. |

|

|

|

|

| EXTERIOR

LIGHTS: |

|

Standard

on PowerStop-MML and PowerStop-MAL

restraint packages, low profile, traffic style, incandescent

red and green lights for communication between truck

driver and dock personnel. A set of caution signs warns

truck driver to “Back In or Pull Out On Green Light

Only”. |

|

|

|

|

| OPERATION: |

|

|

PowerStop-M

- Restraint Only. Once trailer is parked

tight against dock bumpers, the dock attendant inserts

one end of the operating bar under the release lever on

the right hand side of the restraint and lifts up, activating

the restraint. The spring loaded float assembly allows

the restraint arm to move up and down with the RIG

during the loading process. Dock attendant should visu-

ally inspect and confirm that the restraint has traveled

vertically and has engaged the horizontal member of

the RIG. The operating bar can then be returned to its

storage bracket. Dock leveler may be activated and

loading/unloading may begin. When loading/unloading

is complete and the dock leveler is returned to its stored

position, the operating bar is inserted into the top of the

slide track on the restraint. The restraint arm is pushed

down until the release lever locks the restraint arm.

Operating bar is returned to its storage bracket. |

|

|

|

|

| ELECTRICAL: |

|

|

The

PowerStop-M, PowerStop-MML, PowerStop-

MAL vehicle restraint are available as a stand alone

unit or combined electrically with your dock leveler

selection. Electrical requirements for PowerStop-

MML and PowerStop-MAL are 115v single phase

installed in a NEMA 12 enclosure. All electrical

control panel components, connections and wiring

are UL listed/ recognized. Please Note: Unless speci-

fically noted on quotation, all electrical requirements,

including mounting of control box, outside lights and

signs, are the responsibility of others. |

|

|

|

|

| INSTALLATION: |

|

Requires

mounting of restraint unit, operating bar storage

bracket, and when including Dock Alert Communication

System, control panel, exterior lights and signs, in strict. |

|

|

|

|

|

|

|

|

|

PowerStop-MML - PowerStop-M with Manual Dock

Alert™ Communication System Adding a manual Dock

Alert communication system to the PowerStop-M

establishes a clear line of communication between truck

drivers and dock personnel. At the beginning and end

of a loading cycle, the dock attendant positions the

selector switch on the interior control panel to the “Do

Not Service Trailer” position. A flashing red light on the

interior panel warns the dock attendant conditions are

not safe for loading/unloading, while a flashing green

light on the exterior wall indicates the truck is cleared

to approach or depart the dock. Once the restraint

has been activated and the dock attendant confirms the

restraint arm has engaged the RIG, the selector switch

should be placed in the “Service Trailer” position. In this

position the exterior light will flash red warning the driver

not to pull away, while the interior light will be flashing

green indicating safe conditions and to proceed with the

loading/unloading. |

|

|

|

|

| WARRANTY: |

|

|

All

PowerStop-M vehicle restraints feature a full

one (1) year base warranty on all structural, and

electrical parts, including freight and labor charges.

Warrants all com- ponents to be free of defects in

materials and workman- ship, under normal use,

during the warranty period. This base warranty

period begins upon the completion of installation

or the sixtieth (60th) day after shipment, whichever

is earlier. |

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

OPTIONS

FOR THE MANUAL POWERSTOP VEHICLE RESTRAINT |

| Model |

Weight |

Price |

| Standard Dock Alert Models |

| Dock Alert |

25# |

|

| Competitive Dock Alert Models |

| Manual Light System |

20# |

|

| Common Dock Alert Options |

| Door limit switch |

~ |

|

| Explosion Proof Controls |

~ |

Consult

us |

| Stanchion for open dock |

~ |

|

| Common Vehicle Restraint Options |

| Powerstop Wall

Mount Installation Hardware |

~ |

|

| Powerstop Ground

Mount Installation Hardware |

~ |

|

| Wall or Drive Embed

Plate |

~ |

|

| Driveway Plate

(Bolt On) |

~ |

|

| Low Dock Pit Floor Plate

(9414-0056) (Includes 4 Anchor Bolts) |

~ |

|

| 1-2" Cantilever

Bracket |

~ |

|

| 3-4" Cantilever

Bracket |

~ |

|

| 5-6" Cantilever

Bracket |

~ |

|

| 7-8" Cantilever

Bracket |

~ |

|

| 9-10" Cantilever

Bracket |

~ |

|

| 11-12" Cantilever

Bracket |

~ |

|

| 14" Cantilever

Bracket |

~ |

|

| Interlock Terminals (for extra leveler or door switch) |

~ |

|

| Door limit switch |

~ |

|

| Over Travel Audible Alarm |

~ |

|

| Edge Lights |

~ |

|

| Spray Metalized |

~ |

Consult

us |

| Remote Power Pack (hose extra) |

~ |

|

| Explosion Proof Controls |

~ |

Consult

us |

| Stanchion for open dock |

~ |

|

| Combined Controls with Leveler |

~ |

Consult

us |

|

|

Vehicle Restraint, Truck

Restraint, Truck Restraints, Vehicle Restraints, and Manual Powerstop

from your complete source

for material handling equipment. |

Back to Product Category

|